Sale

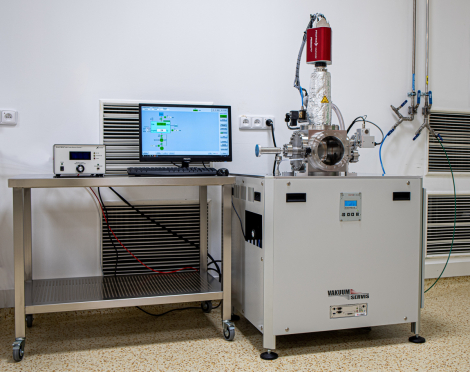

RGA 160 testing system

| Manufacturer: | Vakuum servis |

RGA 160 testing system

Main characteristics

- Multipurpose testing device for RGA (residual gas analysis) analysis of UHV components for cleanliness verification.

- Quantitative outgasing analysis for hydrocarbons, water vapour and other specific chemicals, based on customer needs to prevent molecular contamination.

- Fully Automated Measurement method based on ASML standard GSA 07 2221

- Dedicated control software with fully automated measurement cycle with final acceptance protocol in pdf form.

- Possibility of final plasma cleaning and vacuum bakeout of vacuum components before measurement.

Technical details – standard version

- Oil-free vacuum pumping system with trubomolecular pump and primary scroll pump

- UHV DN160 CF cubical chamber with internal volume of 7 litres

- All-metal vacuum valves

- Quadrupole mass spectrometer Pfeiffer Prisma Pro, mass range 0-200 amu, Faraday +C-SEM detector, open type ion source with Y2O3 iridium filaments

- Calibration gas mixture included

- Integrated heating for automated system bakeout, (temperature can be adjusted up to 130°C)

- Ultimate pressure up to < 5e-9 mbar (for empty chamber, after 24 hrs bakeout)

- Minimal detectable leakrate < 5e-7 mbar.l.s-1 for H2O; < 5e-10 mbar.l.s-1 for CxHy

- Footprint 850x750 mm

Customization possibilities:

- Enlargement of a speciemen chaber up to 40 liters

- Dedicated pumping system for quadrupole analyzer – better stability of measurement performance

- Plasma cleaning unit – helps to keep the system in pristine condition free from hydrocarbons